| Sign In | Join Free | My gimpguru.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gimpguru.org |

|

Brand Name : FUNSONIC

Model Number : FS620

Certification : CE

Place of Origin : CHINA

MOQ : 1 UNIT

Price : Negotation

Payment Terms : T/T,Western Union

Supply Ability : 1000 unit per month

Packaging Details : Packed by Wooden Case

Production Name : Ultrasonic Precision Spraying Machine

Frequency : 20-200khz for Optional

Max Power : 50w

Continuous Spraying Volume Max : 20-1200ml/h/pcs,Scalable

Effective Spraying Width : 2-260mm/pcs,Scalable

Spray Uniformity : <5%

Solution Viscosity : ≤30cps

Input Voltage : 220V±10%/50-60Hz

| Product Type | Intelligent Ultrasonic Precision Coating Machine desktop Type |

| Spray Nozzle Operating Frequency | 20-200KHz (Normally use 60100110120K) |

| Nozzle Power | 1-15W |

| Continuous Spraying Volume Max | 0.01-50ml/min |

| Effective Spraying Width | 2-100mm |

| Spray Uniformity | ≥95% |

| Solution Conversion Rate | ≥95% |

| Dry Film Thickness | 20nm-100μm |

| Solution Viscosity | ≤30cps |

| Temperature Range | 1-60℃ |

| Atomized Particles (Median Value) | 10-45μm (distilled water), determined by the frequency of the nozzle |

| Diversion Pressure Max | ≤0.15MPA |

| Input Voltage | 220V±10%/50-60Hz |

| Exercise Mode | XYZ three-axis, independently programmable |

| Control Mode | FUNSONIC spraying control system, PLC control, 13.3-inch full-color touch screen |

| Control Content | Ultrasonic spraying, liquid supply, heating, ultrasonic dispersion and other systems |

| Liquid Supply Method | Precision injection pump |

| Ultrasonic Dispersion System (Optional) | 20ml or 50ml, 40K, biological grade sampler |

| Rated Power of Ultrasonic Dispersion System | 100W |

Attention:

1. Precipitation of precious metal catalysts: While using a 40K ultrasonic dispersion system in the injector to effectively prevent solution precipitation, material waste can also be saved by shortening the distance from the injector to the nozzle.

2. Selection of nozzle: Choose a convergent or wide nozzle based on the spraying area, and select the frequency according to the solution

3. Spray rate: In order to ensure uniform coating, the spray rate is often set at 0.2 milliliters per minute, which can be adjusted according to the actual situation

4. Heating adsorption platform: Using microporous ceramic heating adsorption platform to ensure the flatness of the membrane, heating the temperature to around 65 ℃ can effectively accelerate the adhesion of the catalyst and the drying of the coating

5. Movement path: The nozzle moves forward, backward, left, and right along the I-shaped pattern, depositing the catalyst suspension layer by layer to ensure that each drop of solution falls evenly on the electrode surface

Scientific Research Laboratory Qualitative Testing Ultrasonic Coating Machine

|

|

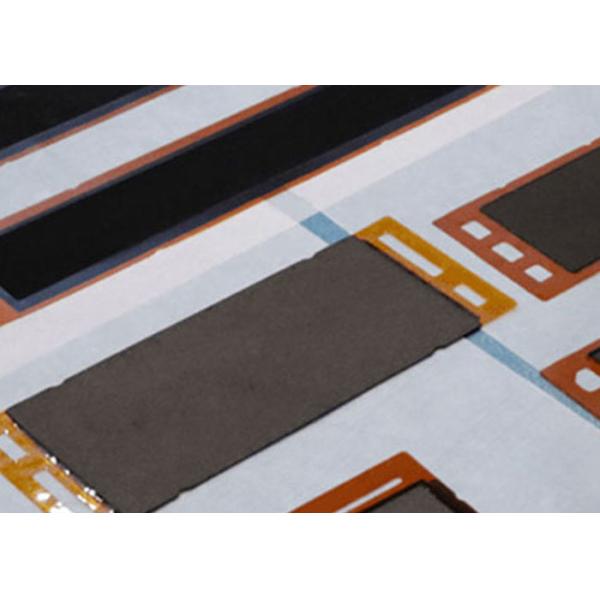

Proton Exchange Membrane Fuel Cell Ultrasonic Spray Coating Images |